After printing a stringy mess, the nozzle of my 3D20 is covered in goo (filament). At room temperature, it’s a nice hard crusty smooth goo. The instructions explain how to clean the nozzle. There’s a nice video (with jolly music) that shows how to do it too:

- Put the printer in heat mode to get the nozzle up to the correct temperature.

- Don’t touch the nozzle – it’s 220 degrees C.

- Remove filament from the top of the print head.

- Don’t touch the nozzle. It’s hot.

- Let the filament ooze through the nozzle for a bit.

- Did we say the nozzle is hot?

- Poke the cleaning tool in at the top and push out any filament.

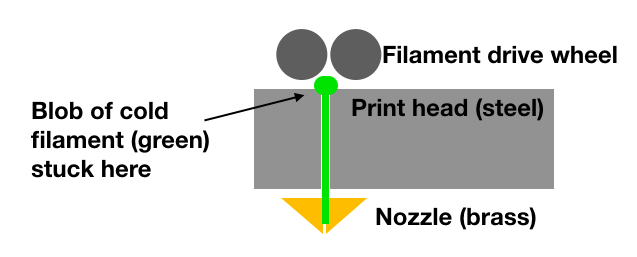

I did this, and the cleaning tool went quite deep into the print head, almost to the nozzle. Then I pulled the cleaning tool out, and as I did so, I realised something had gone wrong. It felt like filament had been pulled out with the cleaning tool. I tried poking the cleaning tool in again, and it wouldn’t go. I guessed that the filament had solidified on the top of the metal part of the print head.

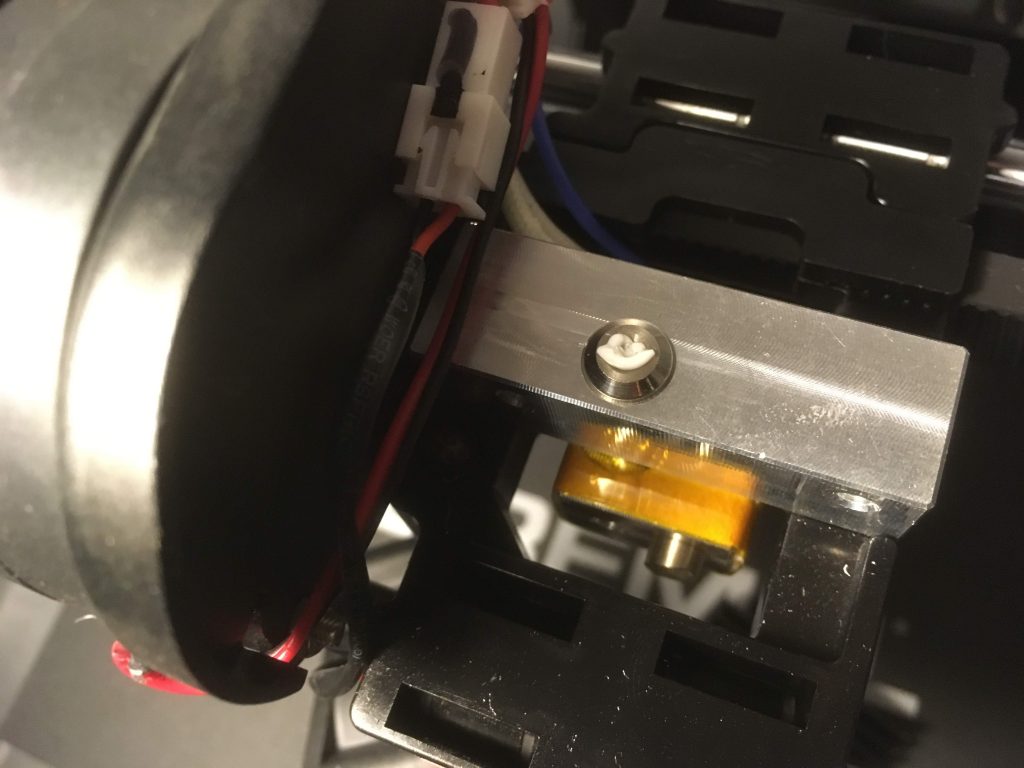

As expected, I’m not the first to experience problems like this. Here is a video, (with no sound), showing how to dismantle the print feeder, to get at the print head. Be careful not to loose the nylon spacers behind the heat-sink, behind the fan.

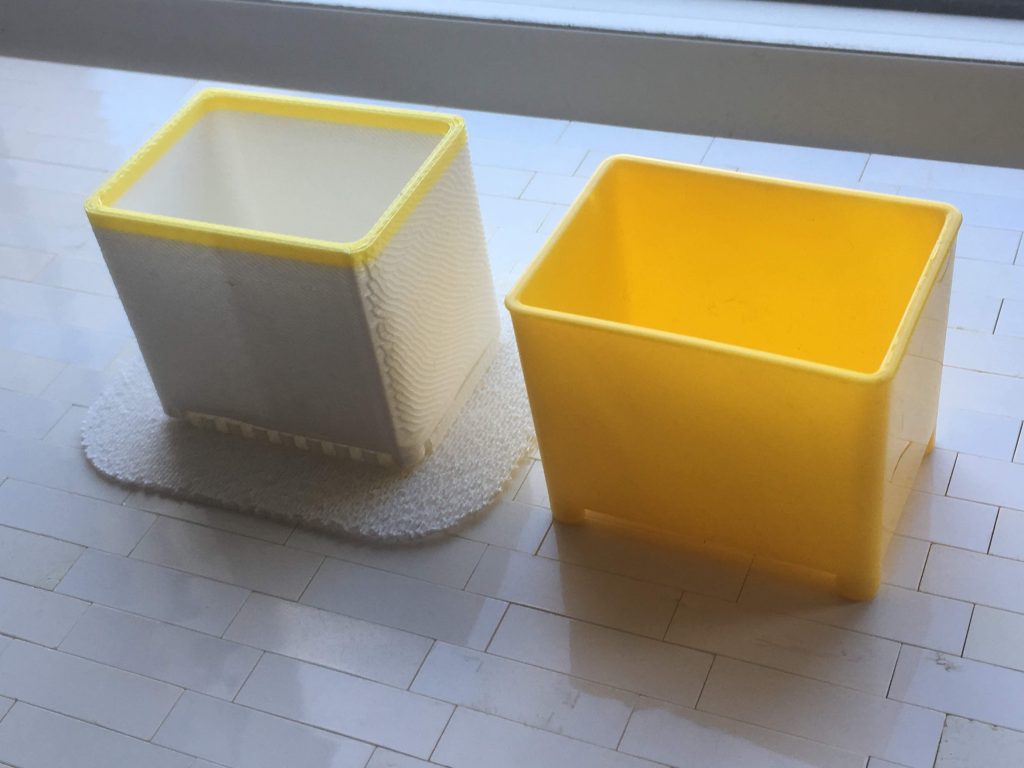

With filament back in the machine, a print job could be started. The results are shown below, and I’ll talk more about it in the next post.

Original (injection-moulded ABS) on the right in yellow.