Following the 3D printer’s instructions online and in the book that came with it, I heated the print head up to working temperature, then carefully used a pair of tweezers to tweeze any filament off the brass nozzle. Doing this a few times removed quite a bit of the stringy stuff.

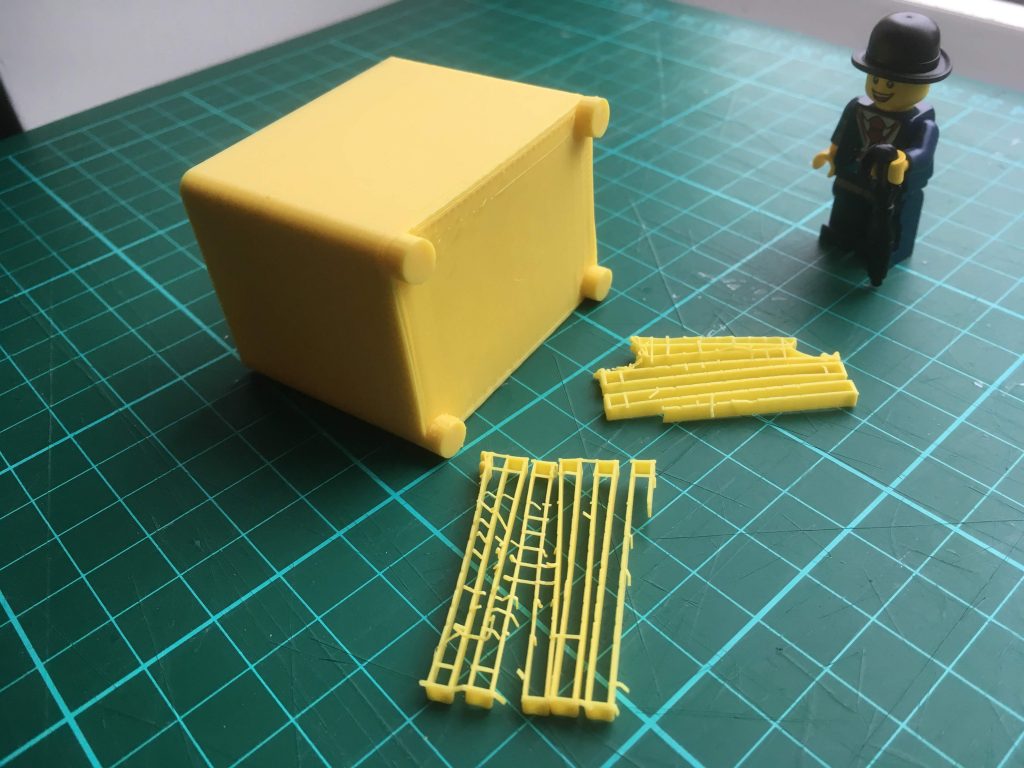

Then I tried another print job, and here is the result, with a Londoner for scale.

Some lessons were learned from this print job, too. The short version is as follows

- Don’t start a print job at 8pm. You’ll get a late night.

- My Cura settings were wrong.

- The stringy version last time was caused by a partly-blocked nozzle.

- Supports are a great idea.

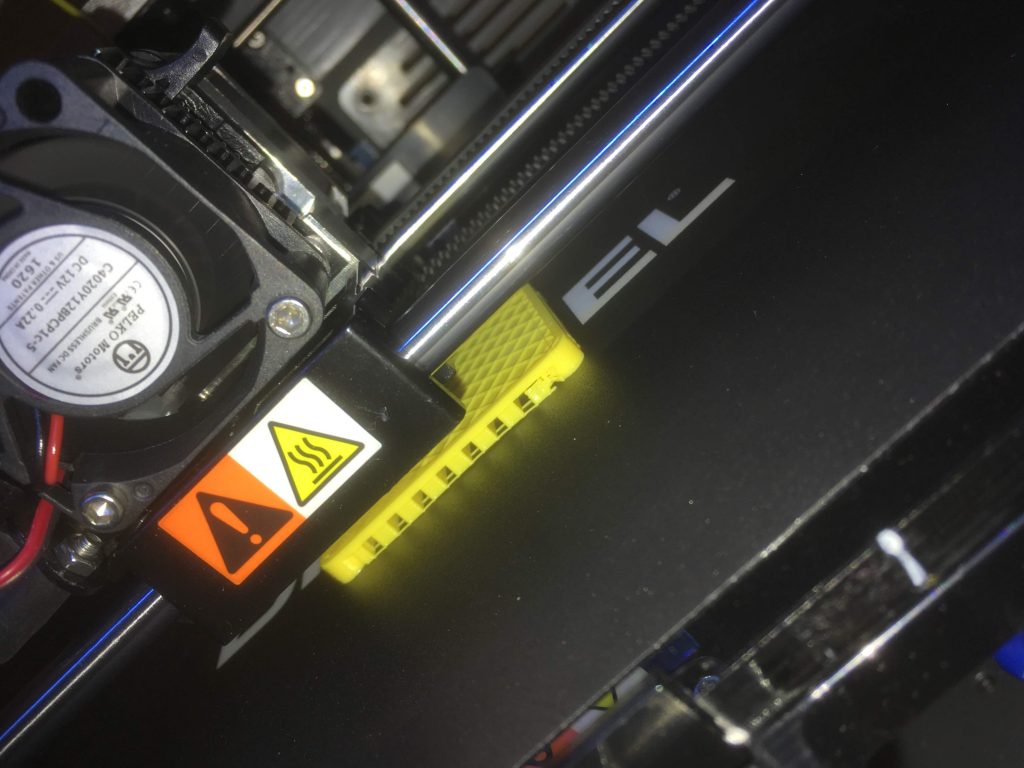

The quality of this box is much better. I think this is because the filament was coming through the nozzle at the right speed. Here is an action shot:

As mentioned before, I’m using Cura to slice the model, because Cura can export to .g3drem files. I corrected my Cura settings by reading the GitHub page of the guy who wrote the .g3drem plugin. Why is reading the documentation the LAST thing we ever do?