It’s been a few months since I did anything with the Shay – life is like that.

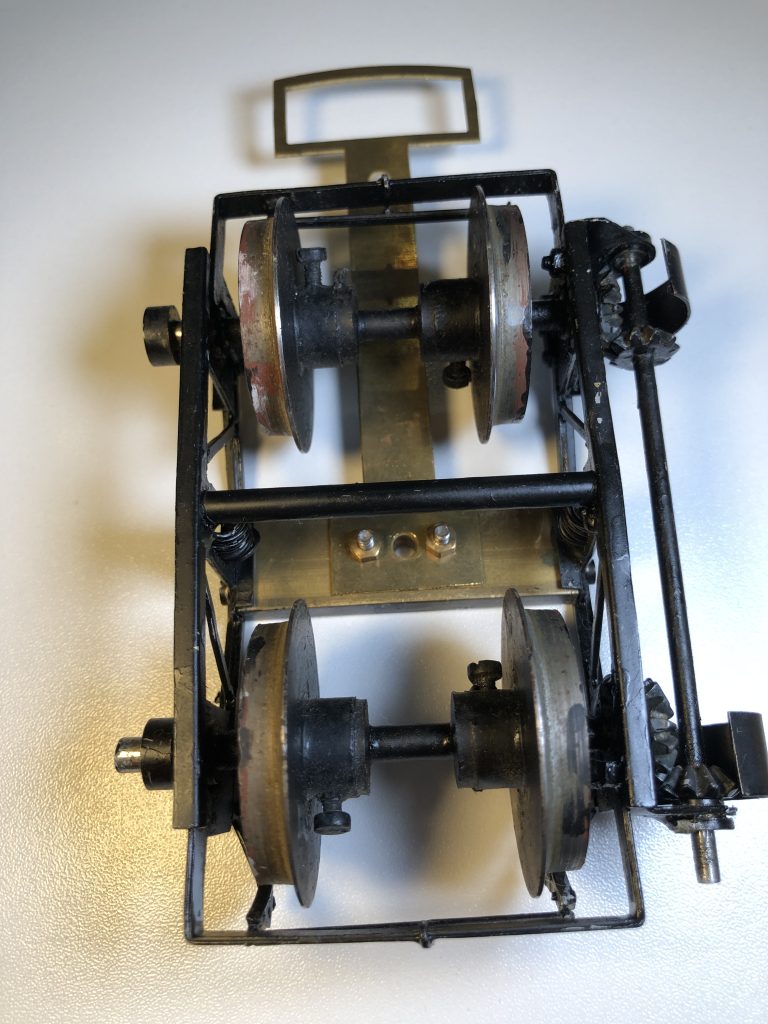

I believe that the wheels of this locomotive were originally designed for G-scale. I say this with reasonable confidence because the flanges are too big, and they bump on the sleepers on 16mm Peco track. Here is one of the bogies, seen from underneath.

I tried a few times to get the bogies apart. Unfortunately, the gears are a tight fit on the axles and won’t come off. Also unfortunately, the bogies are soldered together, and I didn’t want to have to rebuild them, So I investigated how I might reduce the flanges whilst the wheels remained in the bogies.

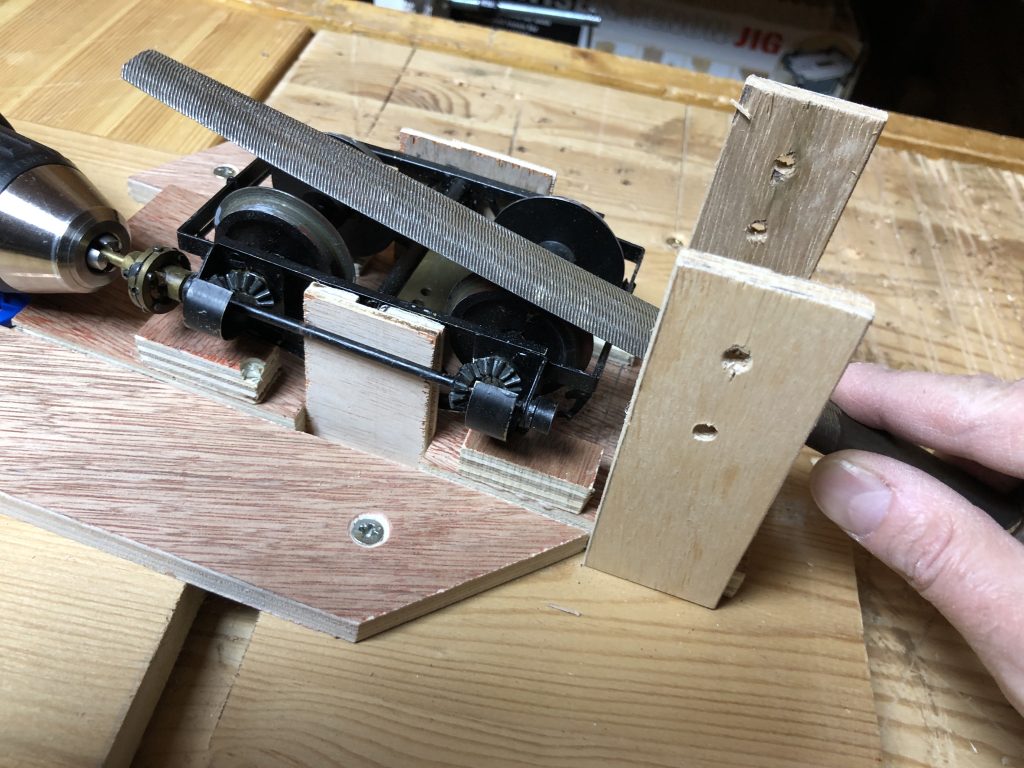

I made a wooden jig to hold the bogie, and attached various bits to a board to support my cordless drill and the jig. There is also another piece of wood that holds the trigger on the drill. Using the driveshaft and gears seemed like a logical thing to do, but when I held the file against the flange to wear it down a bit, I quickly realised that this was putting un-necessary stress on both the universal joint and on the gears. The grub screws also kept coming loose.

So I rotated the bogie-holding jig through 90 degrees and held the axle directly in the cordless drill. This worked much better. It involved removing a boss from the left end of the bogies and tightening the screws that hold the wheel to the axle, but this was much more satisfactory, and in the space of a few minutes I had filed down one wheel sufficiently that it no longer bumped along the track.

Repeat with the other wheel on the same axle.

The jig was adjusted to drive the other axle, and its two wheels were similarly filed down. The exact diameter of the flange is not critical. A bit of filing on the sides of the flange removes any burrs.

Repeat with the other bogie, and the wheels now run properly on the track.